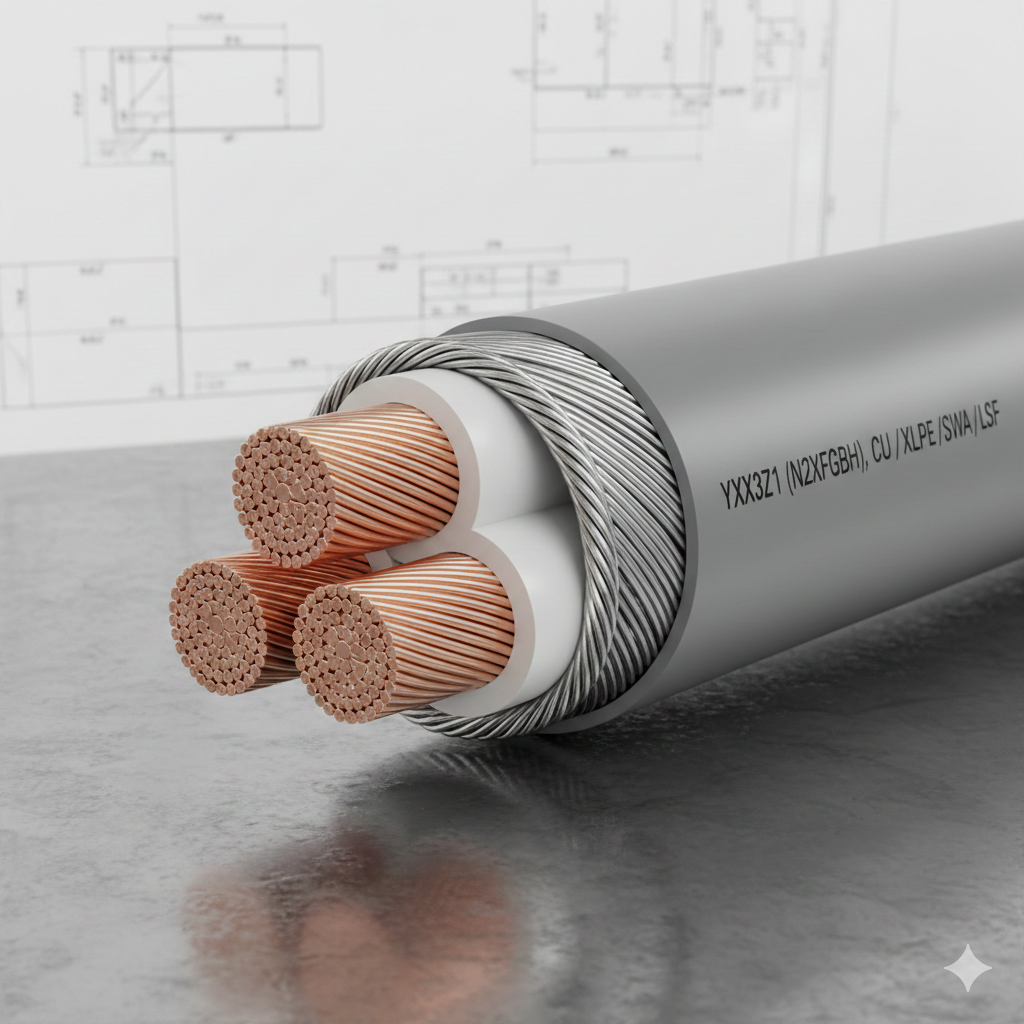

YXZ3Z1 (N2XFGBH) – Cu / XLPE / SWA / LSF

0.6/1 kV halogen free XLPE insulated steel wire armoured power cables

(YXZ3Z1 / N2XFGBH) are designed for power transmission and distribution in fixed

installations where enhanced mechanical protection, fire safety, and low smoke

emission are required.

These cables combine XLPE insulation with steel wire armouring and halogen free

sheathing materials, providing high mechanical strength, reliable electrical

performance, and minimal toxic gas emission in case of fire. They are ideal for

critical infrastructure and industrial applications.

Applications

- Power transmission and distribution networks

- Underground installations and direct burial

- Industrial plants and heavy-duty installations

- Infrastructure and utility projects

- Public buildings requiring enhanced fire safety

- Outdoor installations exposed to mechanical stress

Thanks to their steel wire armouring and halogen free construction, YXZ3Z1

(N2XFGBH) cables are suitable for installations where both mechanical protection

and fire safety are critical.

Cable Construction

- Conductor: Solid or stranded copper conductor

- Insulation: XLPE (Cross-Linked Polyethylene)

- Inner Sheath: Halogen free compound

- Armouring: Steel wire armour (SWA)

- Outer Sheath: Halogen free compound (LSF)

YXZ3Z1 (N2XFGBH) cables are constructed with XLPE insulated copper conductors,

protected by steel wire armouring and halogen free inner and outer sheaths. This

design provides excellent mechanical protection, improved thermal performance,

and low smoke and toxic gas emission during fire.

| Parameter | Value |

|---|---|

| Rated Voltage | 0.6/1 kV |

| Conductor Material | Copper (Cu) |

| Conductor Type | Solid or Stranded |

| Insulation Material | XLPE |

| Inner Sheath | Halogen Free Compound |

| Armouring | Steel Wire Armour (SWA) |

| Outer Sheath | Halogen Free Compound (LSF) |

| Operating Temperature | Max. +90 °C |

| Short Circuit Temperature | Max. +250 °C |

| Installation Type | Fixed installation |

| Suitable for Outdoor Use | Yes |

| Suitable for Direct Burial | Yes |

| Mechanical Protection | High |

| Smoke Density | Low smoke |

| Halogen Content | Halogen free |

| Flame Retardant | IEC 60332-1 |

| Parameter | Description |

|---|---|

| Conductor Resistance at 20°C | According to IEC 60228 |

| Insulation Resistance | ≥ 20 MΩ·km |

| Test Voltage | 3.5 kV |

| Current Carrying Capacity | According to IEC 60502-1 |

| Standard | Description |

|---|---|

| VDE | N2XFGBH |

| IEC 60502-1 | Low Voltage Power Cables |

| IEC 60332-1 | Flame Retardant |

| CE | Compliant |

| RoHS | Compliant |

| Application Area |

|---|

| Underground installations |

| Industrial facilities |

| Infrastructure projects |

| Public buildings |

| Areas requiring high mechanical protection and fire safety |

| Nominal Cross Section (mm²) | Overall Diameter mm (approx.) | Net Weight kg/km (approx.) | Conductor DC Resistance at 20°C (max. ohm/km) | Current Carrying Capacity in Air (A) | Current Carrying Capacity in Ground (A) |

| 2 Cores | |||||

| 2×1.5 | 11.5 | 225 | 12.1 | 24 | 32 |

| 2×2.5 | 12.5 | 275 | 7.41 | 32 | 43 |

| 2×4 | 13.5 | 340 | 4.61 | 42 | 56 |

| 2×6 | 14.5 | 415 | 3.08 | 53 | 71 |

| 2×10 | 16.5 | 570 | 1.83 | 74 | 96 |

| 2×16 | 18.5 | 780 | 1.15 | 98 | 125 |

| 3 Cores | |||||

| 3×1.5 | 12.0 | 250 | 12.1 | 24 | 32 |

| 3×2.5 | 13.0 | 310 | 7.41 | 32 | 43 |

| 3×4 | 14.2 | 390 | 4.61 | 42 | 56 |

| 3×6 | 15.3 | 485 | 3.08 | 53 | 71 |

| 3×10 | 17.5 | 675 | 1.83 | 74 | 96 |

| 3×16 | 19.5 | 940 | 1.15 | 98 | 125 |

| 3×25 | 23.0 | 1420 | 0.727 | 128 | 162 |

| 3×35 | 25.5 | 1810 | 0.524 | 157 | 197 |

| 3×50 | 29.0 | 2450 | 0.387 | 190 | 234 |

| 3.5 Cores (Reduced Neutral) | |||||

| 3×16+10 | 20.5 | 1080 | 1.15 / 1.83 | 98 | 125 |

| 3×25+16 | 24.5 | 1580 | 0.727 / 1.15 | 128 | 162 |

| 3×35+16 | 26.5 | 1970 | 0.524 / 1.15 | 157 | 197 |

| 3×50+25 | 30.5 | 2690 | 0.387 / 0.727 | 190 | 234 |

| 3×70+35 | 35.0 | 3680 | 0.268 / 0.524 | 242 | 291 |

| 3×95+50 | 40.0 | 4960 | 0.193 / 0.387 | 293 | 351 |

| 3×120+70 | 44.5 | 6280 | 0.153 / 0.268 | 339 | 403 |

| 3×150+70 | 48.5 | 7590 | 0.124 / 0.268 | 389 | 458 |

| 3×185+95 | 54.5 | 9630 | 0.0991 / 0.193 | 444 | 521 |

| 3×240+120 | 63.5 | 12580 | 0.0754 / 0.153 | 522 | 611 |

| 4 Cores | |||||

| 4×1.5 | 13.0 | 290 | 12.1 | 24 | 32 |

| 4×2.5 | 14.2 | 365 | 7.41 | 32 | 43 |

| 4×4 | 15.5 | 465 | 4.61 | 42 | 56 |

| 4×6 | 16.8 | 585 | 3.08 | 53 | 71 |

| 4×10 | 19.2 | 825 | 1.83 | 74 | 96 |

| 4×16 | 21.5 | 1150 | 1.15 | 98 | 125 |

| 4×25 | 25.5 | 1760 | 0.727 | 128 | 162 |

| 4×35 | 28.5 | 2280 | 0.524 | 157 | 197 |

| 4×50 | 33.0 | 3150 | 0.387 | 190 | 234 |

| 4×70 | 38.0 | 4380 | 0.268 | 242 | 291 |

| 4×95 | 43.5 | 5980 | 0.193 | 293 | 351 |

| 4×120 | 48.5 | 7540 | 0.153 | 339 | 403 |

| 4×150 | 54.5 | 9420 | 0.124 | 389 | 458 |

| 4×185 | 61.0 | 11840 | 0.0991 | 444 | 521 |

| 4×240 | 69.5 | 15450 | 0.0754 | 522 | 611 |

| 5 Cores | |||||

| 5×1.5 | 14.1 | 335 | 12.1 | 24 | 32 |

| 5×2.5 | 15.5 | 430 | 7.41 | 32 | 43 |

| 5×4 | 17.0 | 555 | 4.61 | 42 | 52 |

| 5×6 | 18.5 | 710 | 3.08 | 53 | 64 |

| 5×10 | 21.2 | 1025 | 1.83 | 73 | 86 |

| 5×16 | 24.0 | 1450 | 1.15 | 96 | 111 |

| 5×25 | 28.5 | 2220 | 0.727 | 130 | 143 |

Technical values are indicative and may vary depending on conductor size,

installation conditions, and applicable standards. For detailed technical data

and project-specific requirements, please contact Envoltra Cable.

Contact & Inquiry

For halogen free armoured cable solutions, technical details, and project-based

pricing, please contact Envoltra Cable sales team.